Common questions of CE MARKING

The word "CE" in CE label must be appropriate for the prescribed rate, can be directly labeled on products or packaging. Regardless of the size of "CE" symbol,....

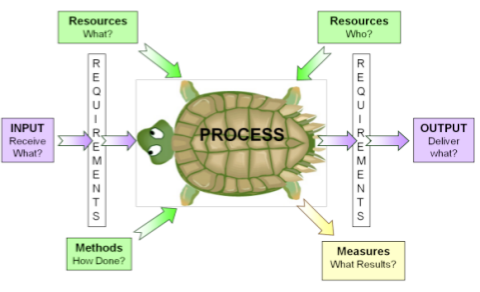

Turtle Diagram is a tool of quality management used to present process-based approach in the 4th principle out of 7 quality management principles according to ISO 9001:2015. 2015. "Process" is a series of activities which use resources to convert input into output, "process-based approach" means activities are approached and resources are used in order to convert input into output. The advantage of "Turtle Diagram" is that we can absolutely control and review processes easily if necessary. Additionally, "Turtle Diagram also supports managers in the determination of correlation and interaction among processes in management system of an organization.

They must detect and manage relevant processes and their interaction to help their organizations to work effectively. As usual, the output of any process is directly created at the next process. Discovery and management of processes are deployed effectively in organizations and the interaction among these processes is called "process-based approach".

Documented Information of quality management system has been built through "an available sample model". "An available sample model" is a system of processes, procedures, principles, instructions, forms copied out of enterprises that applied quality management system and similar manufacturing sector. Copying leads to incompatibility in practical application in enterprises. Incompatibility easily becomes a burden of enterprises during their application, maintenance and improvement on quality management system. This burden is discovered through the coercion of application of process, instruction, form-based which are not theirs due to the ambiguity of content of documents and their misunderstanding about documents. Leaders of some enterprises sometimes mistake "text information system of quality management provided by pre-audit unit is due to principles of International Organization for Standardization (ISO), so they procedures, instructions or processes must be written to achieve requirements.

Therefore, the understanding of system's demands of quality management system through ISO 9001:2015, and the understanding of process-based approach are minimum requirements for leaders and employees in charge of construction of text information system of quality management in enterprises.

Although there is no ISO 9001's requirement which regulates "Turtle Diagram" application to process establishment of quality management system. Nevertheless, Clause 4.4.1 in ISO 9001 requires "Organizations must determine processes which are necessary for quality management system and determine the order and interaction of these processes in the whole organization". "Turtle Diagram" provides organizations with a mechanism with a view to determining and managing relevant tasks of quality management system. This type of diagram is also an effective tool with the aim of understanding processes from the perspective of resource management and helping to identify gaps in organization's structure as well as flaws of text information.

"Turtle Diagram" is described like the following picture:

Process-based approach by "turtle diagram" in ISO 9001:2015

Instructions on how to apply and assess the process through "Turtle Diagram":

- Inputs: At "Inputs" part, organizations need to obtain some accurate information such as requirements, input materials, text information which form the basis for meeting conditions to accerlerate processes. For example: "Delivery proposal form/ Material proposal form" was issued to allow delivery process to be implemented.

- Ouputs: At "Outputs" part, organizations need to identify desired results namely products, result reports,... For example: Output results of delivery are "Delivery form", "Input-output-inventory balance sheet", "Warehouse card".

- With what: needs to determine tools, materials, environmental factors for process and standard implementation.

- Who: needs to identify the performance title and acceptance criteria for relevant titles such as education, pre-audit, experience and skills.

- How: explains how to implement process through steps at work.

- How much? (Bao nhiêu?): Organizations need to plan for KPIs (Key Performance Indicators) or goals for each process to lay foundation for validity and effectiveness assessment of process.

- Supporting processes: Relevant processes are compatible with analysing processes. Examples: supporting processes of delivery can embrace shipment, data update process, forklift truck operation process.

Text information of a process needs to have some following parts:

This is an informative text when a procedure, process, work guide are written and drafted at an organization.

The compatibility between 5M + 1E and turtle diagram:

If some people get used to applying 5M + 1E principles to construction of process, the application of turtle diagram becomes easy to them. 5M + 1E is construed as follows: M1 - Men, M2 - Material, M3 - Machine, M4 Method, M5 - Measurement, E - Environment. The compatibility is construed as follows:

- Who = Men

- With what = Material & Machine & Environment.

- How = Method.

- How much = Measurement.

The application of turtle diagram helps to establish documents (text information) for each process to determine compatibility among processes as well as output results of each process.

Turtle Diagram is widely used in ISO/ TS 16949 - Quality Management System in Automobile Industry, AS 9100 - Quality Management System in Aviation Industry, ISO 22000 - Quality Management in Food Safety and ISO 9001:2015 - Quality Management System.