KNA COOPERATED WITH TUV AUSTRIA HELLAS ON AUDITING FSC STANDARDS IN VIETNAM

After time of exchanging and discussing, KNA CERT has successfully signed a cooperation agreement with TUV Austria on FSC/CoC certification services. Accordingl...

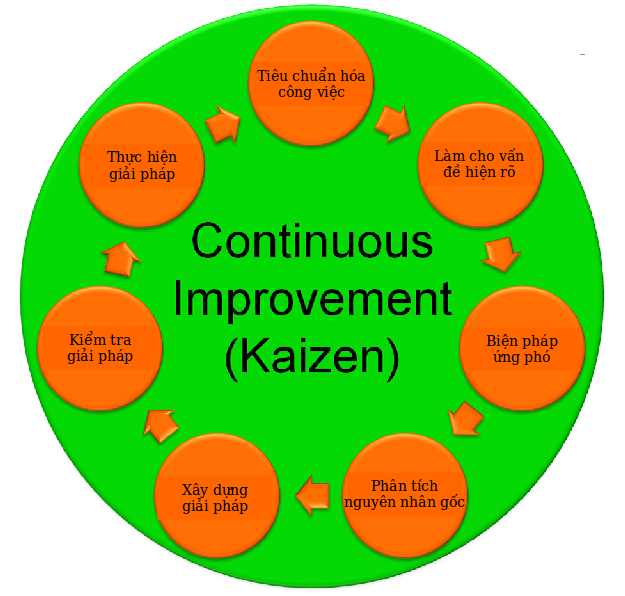

One of the Japanese method to improve quality is KAIZEN. Thanks to KAIZEN, Enterprises can enhance performances as well of quality of products. Let’s take a look inside this special method and its benefits in this article.

Definition of Kaizen

Definition of Kaizen

Kaizen is an ancient term of Japanese. It is combined from two words 改 (“kai”) equal to “change” and 善 (“zen”) equal to better. Thus, Kaizen means ”Change for better” or “constantly innovate”. In English, it is known as “ongoing improvement”.

In a book named “Kaizen: The Key To Japan's Competitive Success”. Kaizen was defined as: “Kaizen means ongoing improvement “.

In a book named “Kaizen: The Key To Japan's Competitive Success”. Kaizen was defined as: “Kaizen means ongoing improvement “.

"Not only applied in working, Kaizen is also applied in private life, social life and working environment. When implemented at work, Kaizen means continuous improvement for anyone from managing board to company’s staff”.

From very early inception, Kaizen was applied to their Toyota brand. Since then, Kaizen became wildly used. Until now, most of big companies all aplly Kaizen to their production. This phylosophy also fit with prvate life of each one.”

In the 1993 edition of "The New Shorter Oxford English Dictionary", the word "Kaizen" was added and defined as follows: Kaizen is continuous improvement of the work process, raising productivity, etc. as a business philosophy. " Today, Kaizen spirit is referred to as a business philosophy, an effective management method that makes the success of Japanese companies. The improvement in Kaizen, however, is a small, incremental improvement and the Kaizen process is impressive for a long time.

According to Western concepts of development, there is always a need for innovation and improvement. Kaizen implementation and adoption are also seen as an innovative and less expensive form of advocacy and development as they enhance the work and record the involvement of the managers as well as their employees to improve the quality of their products and services, at the same time to cut the costs. This is a great attraction for Kaizen because it does not require sophisticated techniques or new technology. In order to perform Kaizen, you only need conventional techniques, such as 7 quality control tools (Pareto charts, causality, organization, control, dispersion, graphs and test cards).

Benefits of Kaizen

The spread of the Japanese Kaizen method began in the 1980s and early 1990s. After large Japanese companies seized major North American companies such as Bridgestone took over Firestone, Sony took over Columbia Pictures.

Kaizen is known as a key to the success of Japanese businesses in the global competitive strategy. Nowadays, there are many companies around the world trying to apply this philosophy of continuous improvement to meet the challenges of harsh competitive environment, continuous development of technology and changes in culture - society.

The success of Kaizen's innovative ideology is the adoption of Toyota. Toyota has about 9 plants in North America and by the end of 2007 it had opened a new factory in Mississipi, producing cars with American workers at or above salaries. Of these, 75% of the cars assembled in North America have parts and materials produced there. Only about 25% of cars are imported from Japan and elsewhere. Still, Toyota made more than $ 14 billion in 2006, while US car manufacturers had to move to China and India to save money.

Continual improvement - the crux of Kaizen's success

The secret of adopting Kaizen into Toyota is to minimize waste in areas such as inventory, reduced working time and waiting, transportation along with the travel of workers. factory. Maximize production redundancy and create a tidy and scientific workplace.

The Kaizen management system helps Toyota build vehicles to transport parts of the assembly line. Since then Toyota has saved nearly $ 3,000 for buying a truck. Applying Kaizen helps to provide the right materials depending on the volume consumed, minimized work in the process and inventory arrangement.

The Kaizen management system helps Toyota build vehicles to transport parts of the assembly line. Since then Toyota has saved nearly $ 3,000 for buying a truck. Applying Kaizen helps to provide the right materials depending on the volume consumed, minimized work in the process and inventory arrangement.

Therefore, workers only have to reserve a small amount for each product and often replenish them based on what the customer actually takes. This reduces the excess of workers, machinery and equipment to increase labor productivity, improve work quality, and reduce production costs.

Suggesting improvement ideas is a process of self-learning and enhancing the working skills of employees, their self-esteem as well as their collective well-being. Thus, employees feel more motivated. At work, they unite to help each other. A, individuals have more motivation to coe up with the idea of improvement, the spirit of collective work, solidarity and create a sense of always reducing the waste.

Improved Kaizen is successfully applied in Toyota

Improved Kaizen is successfully applied in Toyota

Managers, as well as all employees, need to understand and believe in the Kaizen philosophy and try to do it continuously. Thus, all employees and leaders are imbued with the philosophy of CONTINUOUS IMPROVEMENT in thinking, acting. When a philosophy is applied effectively it will form a culture in the company. Editor-in-chief of AutoWeek magazine commented: "It saves not just Toyota's own culture. It is the culture that the Japanese bring to the United States, or at least in their factories. "

At Toyota, Kaizen helped shape the company culture: the culture of behavior between leaders and employees, between employees; saving; the protection of the company's brand; hard work; mutual learning spirit. Kaizen's spirit is also reflected in two of Toyota's key philosophies, "Developing People First" and "Respect for People." "At Toyota, any problem is taken seriously and resolved," said John Robinson, assembly manager. That's why without any management, even an "off-the-shelf" worker can stop the whole chain if it detects an error. "

Conclusion

The success of the Kaizen system helps the business always improve and develop. This philosophy applies and changes the company's activities in a positive and beneficial way. Therefore, if your business wants to apply Kaizen for your business, please contact us KNA Cert Certification Company. We continuously organize Kaizen pre-audit courses to help your company understand Kaizen and apply them in the best way to help improve product’s quality and reduce costs

For pre-audit Kaizen, visit tại đây :